e discussed our five key principles for success with leading automotive COOs, and their perspectives confirm the changes OEMs need to make to sharpen their competitive edge.

OEMs and suppliers are under intense pressure on multiple fronts, from shortening product development cycles and streamlining production, to the transition to electric vehicles and meeting consumer demands for greater customization – and it is the COO who is expected to deliver.

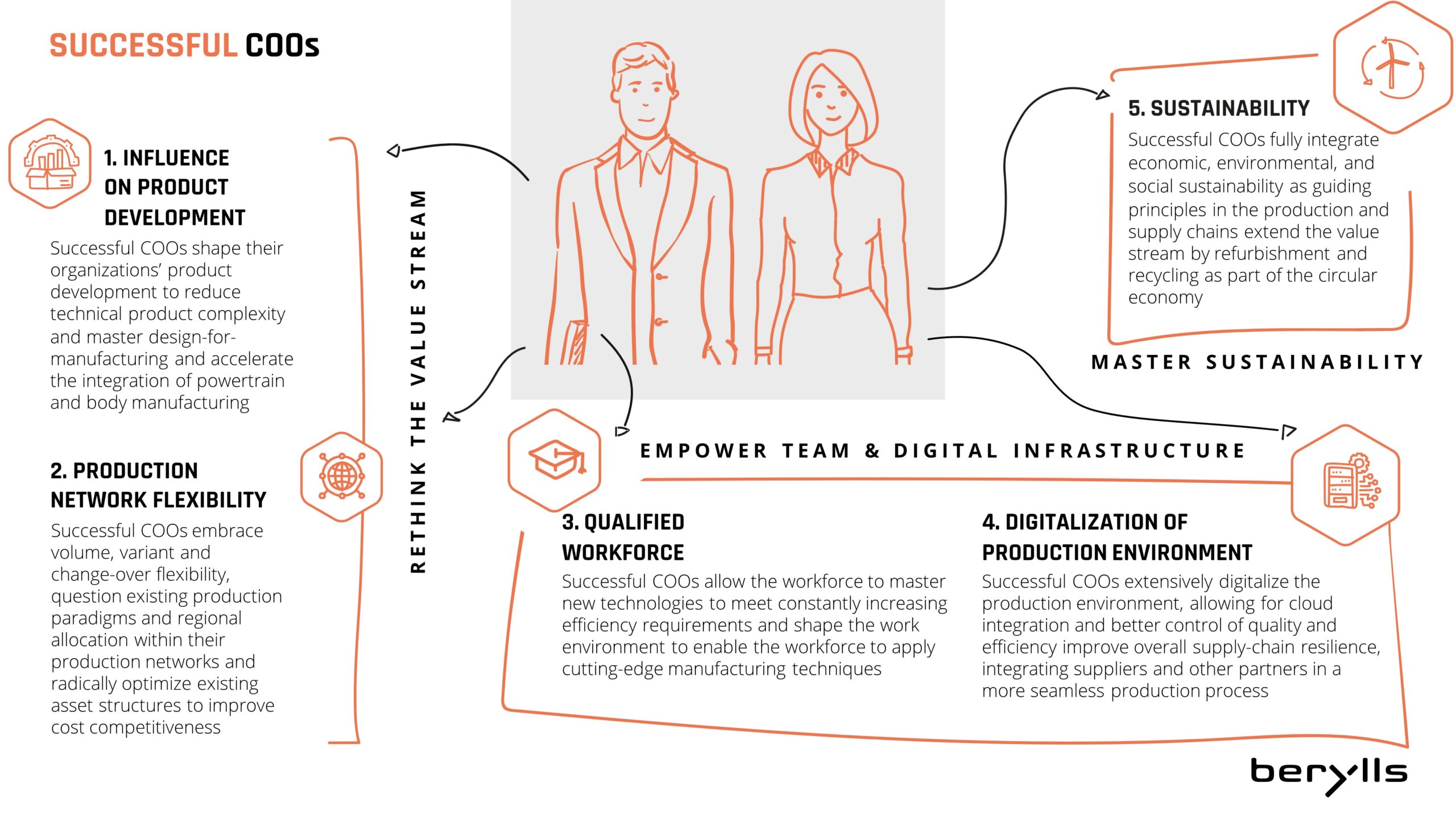

Amid so much disruptive change, our COO Agenda 2021, launched last August, identified five guiding principles for COOs to follow to maintain their companies’ competitive edge:

Influence on product development

Production network flexibility

Qualified workforce

Digitalization of production environment

Sustainability

#1 Influence on product development

#2 Production network flexibility

#3 Qualified workforce

#4 Digitalization of production environment

#5 Sustainability

To take the agenda forward, we interviewed 26 automotive COOs and leading industry production professionals at the end of 2021. Over the course of some very fruitful conversations, for which we thank our interviewees, we asked them to rank our five principles in order of importance to their work. We also asked them to identify any other issues that COOs will need to address in a rapidly evolving market. Two additional themes came to the fore – operational excellence and culture. We regard both as essential enablers of the changes OEMs and suppliers are making.

In the coming months, we will share more detailed insights, starting with two of the priority areas for COOs – production network flexibility and sustainability. We look forward to your feedback on these subjects and will be publishing further insights on the other principles later this year.

“The key challenge when introducing flexibility is to find the optimum,” the COO of one OEM told us. “Do I look at a single plant or the network and how large is the ultimate benefit?” Most of our interviewees confirmed that while their companies are increasing flexibility by focusing on production lines and plants, this is not happening yet at network level. We are convinced that the network has to deliver flexibility, although this does not mean that every single plant in the network has to be fully transformed.

Going forward, we expect successful COOs to embrace volume, variant and change-over flexibility, while challenging current production processes and streamlining assets to improve cost competitiveness.

RELATIVE IMPORTANCE

Relative Importance: Very High

“The key challenge when introducing flexibility is to find the optimum,” the COO of one OEM told us. “Do I look at a single plant or the network and how large is the ultimate benefit?” Most of our interviewees confirmed that while their companies are increasing flexibility by focusing on production lines and plants, this is not happening yet at network level. We are convinced that the network has to deliver flexibility, although this does not mean that every single plant in the network has to be fully transformed.

Going forward, we expect successful COOs to embrace volume, variant and change-over flexibility, while challenging current production processes and streamlining assets to improve cost competitiveness.

Our interviewees agreed that being able to influence product development is a key enabler for achieving flexibility. “The product needs to fit the lines, [so] we need to influence R&D and drastically reduce complexity,” said the plant manager at one OEM, a view shared by many other respondents. We believe that in future the most competitive companies will empower COOs to simplify products through design-for-manufacturing and the integration of powertrain and body manufacturing.

RELATIVE IMPORTANCE

Relative Importance: High

Our interviewees agreed that being able to influence product development is a key enabler for achieving flexibility. “The product needs to fit the lines, [so] we need to influence R&D and drastically reduce complexity,” said the plant manager at one OEM, a view shared by many other respondents. We believe that in future the most competitive companies will empower COOs to simplify products through design-for-manufacturing and the integration of powertrain and body manufacturing.

“A couple of years ago, colleagues smiled when sustainability was mentioned,” the COO of one OEM recalled. “However, ultimately it will give us our license to build cars and is central to our strategy.” Overall, the survey responses indicate that COOs understand why sustainability must be a guiding principle for production and supply chains, with vehicle refurbishment and component recycling also extending the value stream as part of a circular economy in future. However, we found that the motivation of interviewees to take action now to promote sustainability varied between companies.

RELATIVE IMPORTANCE

Relative Importance: High

“A couple of years ago, colleagues smiled when sustainability was mentioned,” the COO of one OEM recalled. “However, ultimately it will give us our license to build cars and is central to our strategy.” Overall, the survey responses indicate that COOs understand why sustainability must be a guiding principle for production and supply chains, with vehicle refurbishment and component recycling also extending the value stream as part of a circular economy in future. However, we found that the motivation of interviewees to take action now to promote sustainability varied between companies.

“It is getting continuously harder to find the right employees, even in major cities where you might think you have a choice,” the COO of one leading OEM remarked in frustration. Meanwhile, another COO stressed that despite introducing various upskilling programs, “you cannot take everyone in your organization on this journey”. We expect remaining employee resistance to change to weaken as it becomes clear that the jobs of the future will only be open to digitally-skilled workers with the ability to use the latest manufacturing technologies.

RELATIVE IMPORTANCE

Relative Importance: Medium

“It is getting continuously harder to find the right employees, even in major cities where you might think you have a choice,” the COO of one leading OEM remarked in frustration. Meanwhile, another COO stressed that despite introducing various upskilling programs, “you cannot take everyone in your organization on this journey”. We expect remaining employee resistance to change to weaken as it becomes clear that the jobs of the future will only be open to digitally-skilled workers with the ability to use the latest manufacturing technologies.

“Currently we make the mistake that IT departments ask what plant managers want – but they do not know what is possible with today’s technology,” a COO observed. Meanwhile, a plant manager said that his company was only collecting data, without deploying data analytics to add value and enable better decisions. These observations should act as a wake-up call for COOs to make production digitalization an urgent priority, in order to strengthen supply-chain resilience and integrate suppliers and other partners in a more seamless process.

RELATIVE IMPORTANCE

Relative Importance: Medium

“Currently we make the mistake that IT departments ask what plant managers want – but they do not know what is possible with today’s technology,” a COO observed. Meanwhile, a plant manager said that his company was only collecting data, without deploying data analytics to add value and enable better decisions. These observations should act as a wake-up call for COOs to make production digitalization an urgent priority, in order to strengthen supply-chain resilience and integrate suppliers and other partners in a more seamless process.

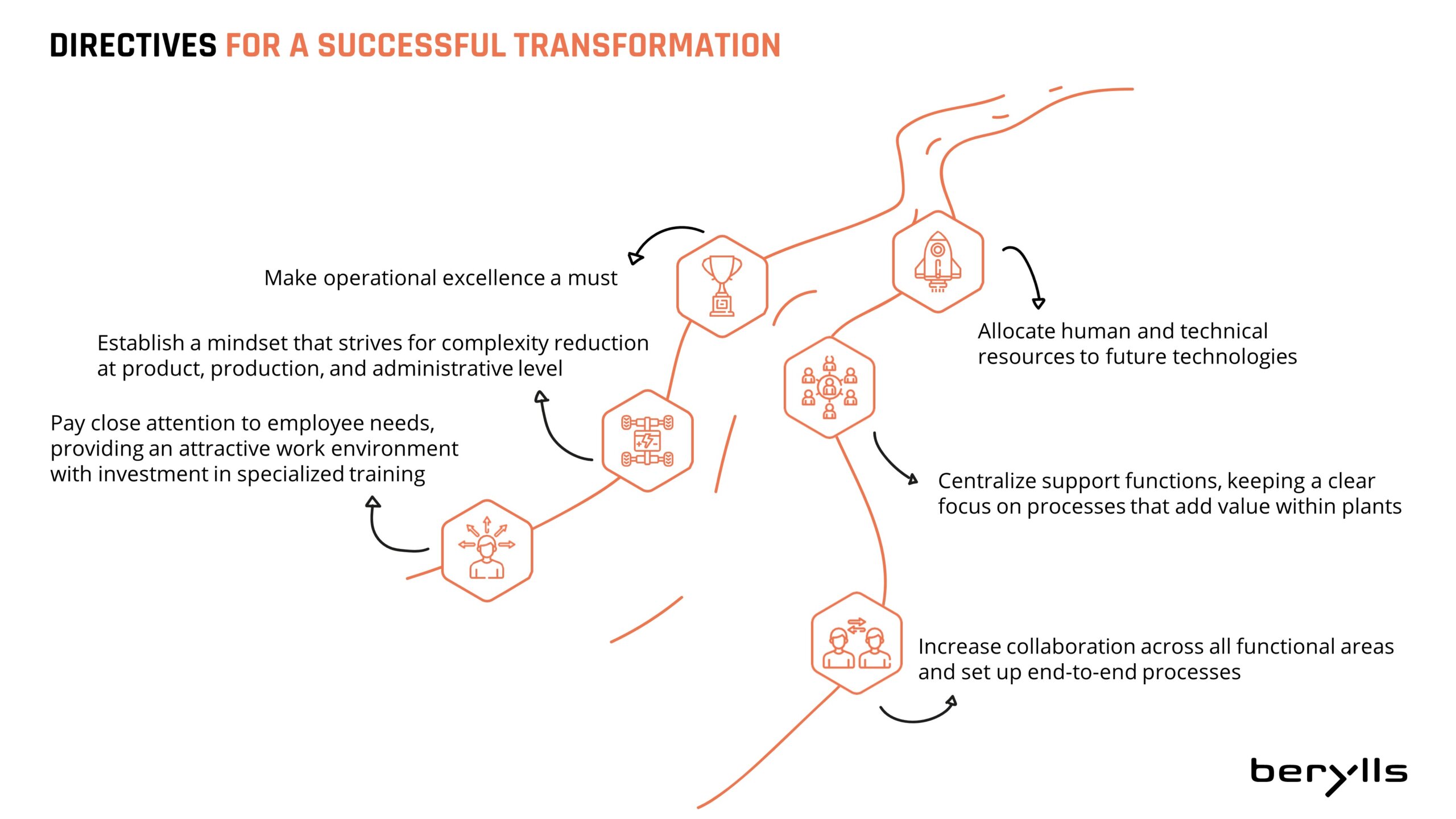

Berylls agrees strongly with the consensus among our interviewees that the two following elements are essential for success as the industry’s transformation accelerates:

“We still need to get better at the things we are currently doing,” the COO of one leading auto supplier declared. “We need to be more disciplined and follow our processes more stringently, not forgetting our continous improvement processes.” Other survey respondents echoed the same viewpoint, especially in the context of increasing competition from China.

However, this is not just about going back to the basics of efficient manufacturing. By reducing costs, operational excellence will enable OEMs to invest in the flexible factories they need.

“We still need to get better at the things we are currently doing,” the COO of one leading auto supplier declared. “We need to be more disciplined and follow our processes more stringently, not forgetting our continous improvement processes.” Other survey respondents echoed the same viewpoint, especially in the context of increasing competition from China.

However, this is not just about going back to the basics of efficient manufacturing. By reducing costs, operational excellence will enable OEMs to invest in the flexible factories they need.

COOs must ensure they have the right culture in place to support implementation of the key guiding principles for success. “We need to introduce a high-performance culture if we want to stay relevant in the future,” one COO said. Yet the experience of many respondents suggests this is easier said than done. “The difficulty is that culture is much harder to influence than production KPIs,” said the COO at another OEM.

For example, it is far more difficult for a production environment to switch to agile ways of working, compared with the sales or other office-based parts of the organization. Nonetheless, COOs cannot ignore such issues – not least because an attractive culture is critical for recruiting and retaining the best talent.

COOs must ensure they have the right culture in place to support implementation of the key guiding principles for success. “We need to introduce a high-performance culture if we want to stay relevant in the future,” one COO said. Yet the experience of many respondents suggests this is easier said than done. “The difficulty is that culture is much harder to influence than production KPIs,” said the COO at another OEM.

For example, it is far more difficult for a production environment to switch to agile ways of working, compared with the sales or other office-based parts of the organization. Nonetheless, COOs cannot ignore such issues – not least because an attractive culture is critical for recruiting and retaining the best talent.

We are grateful to our interviewees for sharing their time and insights, and enriching our analysis of the most pressing issues confronting COOs today. In particular, our discussions have highlighted the importance of production network flexibility and sustainability. During the coming months, we will be producing follow-up reports on these subjects, as well as the other three principles of product development, workforce qualification and digitalization. Drawing on this research, we look forward to continuing our engagement with COOs about the next steps they need to take to maintain their competitive edge.

Heiko Weber (1972), Partner at Berylls Strategy Advisors, is an automotive expert in operations.

He started his career at the former DaimlerChrysler AG, where he worked for seven years and was most recently responsible for quality assurance and production of an engine line. Since moving to Management Engineers in 2006, he has been contributing his experience and expertise to projects for automotive manufacturers as well as suppliers in development, purchasing, production and supply chain. Heiko Weber has extensive experience in the development of functional strategies in these areas and also possesses the operational management expertise to promptly catch critical situations in the supply chain through task force operations or to prevent them from occurring in the first place.

As a partner of Management Engineers, he accompanied the firm’s integration first into Booz & Co. and later into PwC Strategy&, where he was most recently responsible for the European automotive business until 2020.

Weber holds a degree in industrial engineering from the Technical University of Berlin and completed semesters abroad at Dublin City University in Marketing and Languages.